STEP 3: JOINING TWO WORKPIECE EDGES TOGETHER

Before Proceeding, CLICK HERE to see a listing of Safety Rules that will help you avoid Personal Injury.

To view a brief (few-seconds long) video clip of each step being

performed click on this icon

wherever you see it.

wherever you see it.

Install the drill bit you're planning to use in the chuck.

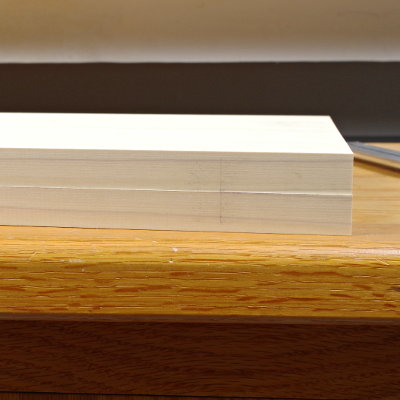

Align your bit's tip with one of your vertical lines and move your worktable up or down until the tip of the bit is half the distance of your boards' thickness (an approximation is acceptable).

Remember, in step #3 above you drew "X"s on the boards'

surfaces. Only by being certain that the same (goodgood)

side surfaces will be in perfect alignment when they are glued together.

Rotate the quill lock dial to the hole depth you want... and lock this setting by tightening the quill feed stop handle on the back side of the headstock. This will limit bit travel to this depth.

Note: Adjust the quill stop mechanism to bore your holes to half the length of the dowels you're using, plus about 1/32" to 1/16"

Now, release the quill lock handle on the front

side of the headstock.

Turn on the machine, adjust to the appropriate speed recommended for your bit size and type and material you're drilling.

CLICK HERE for a chart of recommended speeds.

See How Simple That Was!

Now that you've learned all about your Shopsmith Horizontal Boring Machine, you're ready to move on to the next woodworking operation -- using the Shopsmith 12" Disc Sander. Watch your Mailbox for the Disc Sanding email, Coming soon!

WANT MORE INFORMATION ON HORIZONTAL BORING? CLICK HERE!

© SHOPSMITH - DREAM IT! BUILD IT! SHARE IT!