Book An Appointment Today!

12 NOON - 3:00 PM

Monday - Friday • Eastern Standard Time

Only $19.99 for Your First 15 Minutes & $1.00 Per Minute After

HOW IT WORKS:

| ✓ WARRANTY |

✓ NO WARRANTY |

If your equipment is under Warranty,

call our Customer Care Line at

(937) 890-5197 at no charge to you. |

If your equipment is Not Under Warranty, or you acquired it from a source other than Shopsmith, contact a Shopsmith Tech Expert. |

YOU ASKED FOR IT, WE ARE DELIVERING

With a long heritage of over 63 years and 600,000 plus machines in circulation, our Customers have asked for more access to Shopsmith Engineer Support to:

-

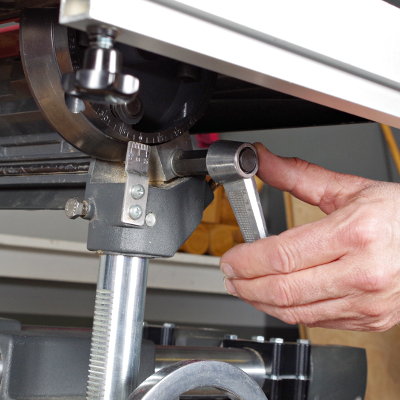

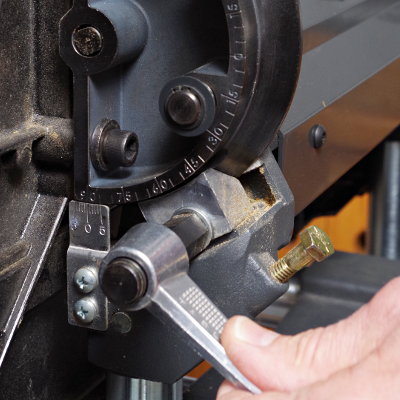

Provide recommendations for keeping your machine operating at optimum efficiency

-

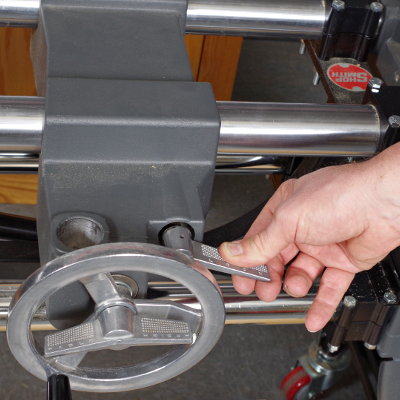

Help guide you through a procedure

-

Assist with source materials such as diagrams, manuals, etc.

-

Guide you through part selection for a technical issue

-

Direct you to the wealth of "Getting Started" Materials

-

Or even just to walk you through how to get started!

The Shopsmith Engineering Team is lead by our Shopsmith Engineer, a leading Quality Assurance Professional And 40+ Year Shopsmith Veteran. If his team can't help, it's likely nobody can.

While we wish we could bottle Shopsmith Experts, and have unlimited resources, they just aren't available.

So, we have created a special Shopsmith Engineering Support Line especially dedicated for Equipment

No Longer Under Warranty. (Our equipment is such high quality; it lasts and lasts!)

| # |

WHAT |

HOW |

| 1 |

Schedule an Appointment |

Book Online |

| Call Customer Care at (937) 890-5197 to Schedule For You |

| 2 |

Pay by Credit Card |

Provide your Credit Card information to bill you for:

- $19.99 for the first 15 Minutes of your call.

- Any time over 15 minutes will be billed at $1.00 per minute

- You will be quoted for estimated additional time if your call takes longer than 15 minutes.

- No Money will be refunded for Less than 15 minutes

|

| 3 |

Get The Most From Your Call! |

When Scheduling Online Yourself, will be able to:

- Schedule your appointment & receive a confirmation

- Provide information on what you need so the Tech Expert can prepare for your call

- Include pictures or videos to assist your Tech Expert

|

| Calling Engineering Technical Support Directly will allow you to have immediate response if they are available, and do not have a scheduled appointment, during 12:00pm & 3:00pm, M-F, Est. |

| Calling our General Customer Care Line will allow you to have a Representatives schedule your Shopsmith Engineering Support Appointment so you don’t have to. They will direct you through how to provide information to the Shopsmith Engineering Support Team. |

We Look Forward to Speaking with You!

wherever you see it.

wherever you see it.