|

The

Molder or Shaper?

Choose the best tool for you!

Molders

and shapers are cutting tools that truly elevate woodworking projects

to a new level of professionalism. Using either one of these unique

cutting tools allows you to create, in your own shop, what the pro’s

produce in their factories. Not having a molder or shaper limits

the potential of the woodworking you can do. Molders

and shapers are cutting tools that truly elevate woodworking projects

to a new level of professionalism. Using either one of these unique

cutting tools allows you to create, in your own shop, what the pro’s

produce in their factories. Not having a molder or shaper limits

the potential of the woodworking you can do.

Now

when you look at the profiles available for molders and shapers,

you may wonder just exactly what the difference is between the two

tools. You’re not alone. Both the molder and shaper have a lot in

common – especially profiles – but just how you use these profiles

does make a lot of difference.

To clear up the issue of which tool is best for you and your projects,

here’s a short guide to the molder and shaper.

Like

Two Peas in A Pod

The

function of both the molder and shaper is to add decorative or functional

touches to the edges and surfaces of wood. You’ve seen these tools

used in such things as tabletop edges, window and door construction,

glue joints, and decorative moldings in the home. The

function of both the molder and shaper is to add decorative or functional

touches to the edges and surfaces of wood. You’ve seen these tools

used in such things as tabletop edges, window and door construction,

glue joints, and decorative moldings in the home.

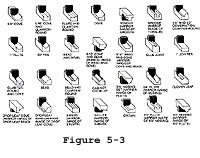

To accomplish all these cuts, there are a wide variety of profiles

available for both the molder and the shaper. Of the many profiles

available, some profiles are unique to one tool or the other, but

there are a wide variety of profiles available for both tools.

As similar tools, molders and shapers are both capable of forming

glue joints – an edge treatment that increases the gluing surface

and provides accurate alignment when gluing stock edge to edge.

And both tools are capable of forming drop-leaf joints, window and

door sashes, as well as a wide variety of decorative edge treatments

like bead-and-cove, ogee, and cloverleaf.

As

Different As Night And Day As

Different As Night And Day

But even though the molder and shaper are similar as far as many

of the profiles go, there’s a big difference when it comes to actually

using the tools and actually forming the profiles.

First

of all, the molder is a table saw attachment that mounts to the

horizontal spindle beneath the worktable. A heavy steel disc holds

three 1-inch wide matching cutting knives and this disc rotates

at about 3500 RPM ("R" on the speed dial).

Using

the molder is easy. Simply set up the Mark V in the horizontal position

with the lower saw guard in place. Mount the Molder Head (with the

desired knife profile installed) on the 5/8" Molder Arbor. Then

install this assembly on the headstock quill. Lower the table over

the molder head.

Next,

place a special Molder Table Insert (Mark V 510, Mark V 500) in

the tabletop and mount the rip fence to the table. The rip fence

here guides the stock as it passes over the rotating molder knives.

To mold the surface of stock, use a Push Block, to keep the stock

flat against the table and your hands safely out of the way.

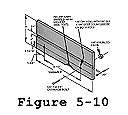

Figure

5-10 When molding the edge of stock, a simple wooden fixture is

attached to the fence so the knives will not hit the rip fence.

The

molder is best suited for adding decorative touches to straight

work such as custom room trim and picture frames.

The

shaper, unlike the molder, requires the Mark V to be set up in the

vertical position. With the machine in the vertical position, the

worktable is perpendicular to a 1-inch wide profiled three-lip shaper

cutter mounted to an arbor. Unlike the molder, the stock is passed

by the spinning cutter – not over it – and the stock is guided by

the use of either a shaper fence or a rub collar with a starter

pin.

The Shaper is best suited for forming decorative edges on straight

and curved edges.

What The Difference Means

Since the ideal way to handle stock on a worktable is to have the

stock flat – the molder and shaper each have distinct advantages

and disadvantages.

First of all, the molder is best suited for forming a profile on

the flat face of stock as it’s passed over the rotating knives.

This application is commonly used with door and window frame moldings,

picture framing stock, and surface treatments of furniture components

like table aprons or chair rails.

Forming

a profile on the edge of stock is possible with the molder, but

any stock over 5 or 6 inches wide requires the added support of

a vertical fence extension. This extension is easy to make and greatly

aids in the safe handling of the stock (Figure 5-10 for plans).

When forming the end of a narrow but long piece of stock (like a

door stile or rail), a special jig or accessory must be used.

Shopsmith

Tenon Master 555479 - Tenon

Master Jig

The

major limitation of the molder is that it’s only capable of forming

profiles in a straight line since all stock must be guided with

the rip fence in place.

The

strong suit of the shaper, on the other hand, is that the table

is perpendicular to the cutter. This means that as the stock is

held flat on the table, the edge of the stock can be safely profiled

as it passes past the cutter.

The

shaper, when equipped with a special shaper fence, is capable of

forming profiles on straight edges like the molder. But the major

advantage of the shaper is that, when equipped with a starter pin

and a rub collar, can form profiled edges on curved stock. And because

the shaper is mounted on the main spindle above the worktable, it’s

possible to shape inside edges. With both of these edge treatments,

the large worktable surface supports stock without the need of any

special jigs. A shaper then is capable of forming the outside edge

of a large oval tabletop or the inside edge of a round picture frame.

Decisions, Decisions

Making a choice between a shaper or molder attachment may seem difficult

– and it is for most woodworkers. Each attachment has its strong

suit – the molder for surfaces and the shaper for curves. And each

tool has a shared ability – forming decorative edges on straight

stock.

To

help with the problem of which tool you need, look at the next project

you want to build and get the appropriate attachment(s) for that

project along with the required cutters or knives. If you’re going

to be making, plaques, oval or round picture frames, or kitchen

cabinets with curved rails, get a shaper. The addition of decorative

edges to these projects would certainly add a real degree of professionalism

to your work.

If, on the other hand, you plan on making new trim for a remodeled

room, picture framing stock, or straight decorative moldings for

furniture pieces, select the molder. You’ll even find the molder

great for adding decorative touches to porch railings, fencing,

and a host of other outdoor projects. For more complete information

on the molder and shaper, refer to 555069, Power Tool Woodworking

for Everyone.

Choosing

the right tool for the job is important from both a safety and an

economic standpoint. Look through the literature for the tool yu

need. Remember that each accessory requires a special insert and

mounting device – a 1/2" arbor for the shaper cutters and a 5/8"

molder/Dado arbor for the molder head that holds sets of 3 matched

molding knives.

Whichever

accessory you choose – the molder, the shaper, or both – you’ll

find your woodworking taking on a whole new dimension.

|