|

|||

Articles and Projects

| Back to Article and Project Index | |

|

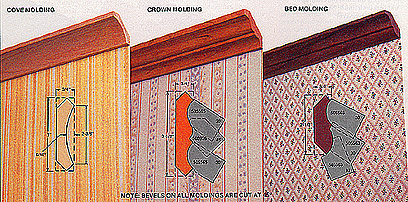

Woodwork You Can Look Up To Doing your own room remodeling offers tremendous satisfaction for several reasons. Most importantly, you know you're doing'it'yourself and you can take pride in seeing the fruits of your labor - a room that's fresh and different. Another cause for satisfaction is saving money by doing'it'yourself, using your own time and resources. But, the real pleasure of room remodeling discussed in this series is in knowing what you've done is unique - making woodwork that's not available to the average homeowner. In this article, we take on ceiling moldings. Designed to cover the seams where the walls meet the ceiling, these moldings do double'duty by also providing an eye'pleasing transition from one surface to another. Again, as with other moldings, design and type of wood allow you to add personality to your room. Here's how to create ceiling moldings for your room: Plan your molding. There are three kinds of ceiling moldings you can make - crown,bed and cove. An example of each is illustrated below. Crown and cove moldings are always "sprung" meaning that they have beveled edges that rest on the ceiling and wall, thereby spanning the ceiling/wall joint. This spanning allows the molding to readily adjust to minor irregularities and provide a clean line where it meets the ceiling or wall. Bed molding can be either sprung or plain - the latter type fitting snug into the joint. Use one of the designs illustrated below or create the profile you want by arranging molding knives in various positions. Prepare stock. It's essential you use straight, true and clear stock for your molding. For our examples we used walnut, cherry, and oak. Rip stock to required widths. Prepare enough extra stock to allow for cutting errors. Cut the profiles. As you can see by the crown and bed moldings we feature, using just a couple of molding knives yields attractive profiles. The cove molding, on the other hand, uses no molding knives; rather, it's done entirely on the table saw. Be sure to always use push blocks, push sticks, feather boards and roller stand for safety. Bevel the molding. After you have completed the profiles, bevel the edges of the molding on the table saw. Tilt the table 45 degrees, mount the rip fence below the blade and use a feather board to help guide the stock. Install the molding. Start installing the ceiling molding on the longest wall first. Drill 7/64" pilot holes for 8d finish nails and nail the molding through the plaster or drywall into the upper wall plate. For large moldings, nail through to the ceiling joint. Cut the molding just a trifle long so it can be lightly sprung into place. If the molding isn't long enough, use a miter lap joint to join two shorter pieces. Install the remaining molding by mitering the outside corners and coping (see footnote) or mitering the inside corners. Finishing touches. Countersink the nails and apply the finish of your choice. Fill the nail holes with wood putty that matches the color of your finished molding. (Click in image for a larger picture) For

detailed information on the installation of molding and how to miter

and cope joints, refer to: |