|

Bowl

Turning on the Shopsmith MARK V

By Dick Gerard

As

I tell my students, there are no right or wrong ways to turn. If

you are happy with a particular tool making a particular cut or

scrape, and if you are pleased with the end results, then that is

the "right" way to do it.

The

Secrets of the Gouge

Using

the gouge to turn bowls has been explained in books such as "Creative

Woodturning" by Dale Nish. This book, and others, can show you the

proper way to handle a gouge. Additionally, many video tapes are

available. The best way to learn, is of course to take lessons from

someone who knows how, lots of practice and follow these 10 secrets

to using a gouge:

-

Keep

it sharp

-

Keep

the bevel LIGHTLY rubbing the wood.

-

Keep

it sharp.

-

Don’t

grip the handle as if you were trying to choke a snake.

-

Keep

it sharp.

-

Keep

loose. Relax. Turning is FUN!

-

Keep

it sharp.

-

Roll

the flute in the direction of the cut.

-

Snuggle

in close to the lathe. Use a compact stance.

-

Keep

it sharp!

Shopsmith

MARK V Advantages

For

faceplate turning of plates, platters, and bowls, the Shopsmith

MARK V offers two distinct advantages over most other lathes. First,

the tool rest and headstock assemblies may be moved to the right

hand end of the ways. This allows the use of long handled tools

without interference with the ways as is common on most other lathes.

Second, by locking the quill in an extended position, the tool rest

may be placed behind the turning. This allows the turner to reach

areas of a turning that may require modification as the turning

progresses.

Preparation

of the Bowl Blank Preparation

of the Bowl Blank

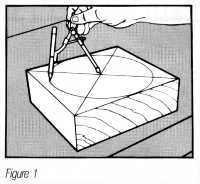

First, select your turning stock, Next, inspect the stock for visible

defects that would hinder turning or that would force a change of

design. Then, decide which surface will be the TOP of the bowl.

This surface will hold the faceplate as you turn the OUTSIDE form.

Next, using a straight edge, draw intersecting lines through opposing

corners. Where the lines cross determines the center point of the

turning. Using a compass, draw the largest circle possible. (Figure

1) Make sure that the compass leg leaves a distinct impression at

the CENTER point. Using the Bandsaw, cut the blank into a circular

form. Next, inspect the freshly cut edges to see if you have uncovered

previously hidden  defects.

If new defects are found, then consider whether they will be eliminated

in the turning process, or whether you should re-orient the turning

blank by use of a new center. Whatever the outcome, also inspect

the bowl blank to ensure that you have used the grain and figure

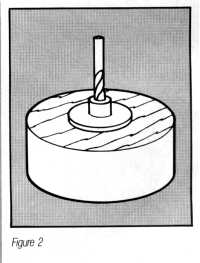

to the best extent. Next, place a 5/8" brad-point drill bit in the

depression left by the compass point. Then slide the appropriate

size faceplate over the drill bit and, using sheet metal screws

(number 12 or 14, 1" to 1-1/4" long), fasten the faceplate to the

wood. (Figure 2) Remove the drill bit and proceed to the lathe. defects.

If new defects are found, then consider whether they will be eliminated

in the turning process, or whether you should re-orient the turning

blank by use of a new center. Whatever the outcome, also inspect

the bowl blank to ensure that you have used the grain and figure

to the best extent. Next, place a 5/8" brad-point drill bit in the

depression left by the compass point. Then slide the appropriate

size faceplate over the drill bit and, using sheet metal screws

(number 12 or 14, 1" to 1-1/4" long), fasten the faceplate to the

wood. (Figure 2) Remove the drill bit and proceed to the lathe.

On

to the Lathe

Check to make sure the speed dial is at the lowest possible speed.

Further, check that the workspace is clear, there are no impediments

to safe walking and that you have adequate lighting. After the wood

is mounted on the lathe, rotate the stock by hand to see if there

are any "heavy" spots in the bowl blank. Most timbers are NOT uniformly

dense. When satisfied with the balance, position the tool rest as

described earlier and again rotate the stock to make sure that the

wood clears the tool rest. About 1/8" clearance is sufficient. After

donning ear, face and lung protectors, move to the left of the headstock

and switch on the power. Almost immediately, you can tell whether

or not the piece needs further balancing. If it does, immediately

switch off the power, ty another center, or trim the high spots

with the Bandsaw, and try again. On larger pieces and for bowls

made from heavily figured timbers, always begin by using the tail

stock and a ball bearing center for additional support. Assuming

the blank is balanced, start the motor and leave the speed dial

at "slow" to rough down the outside and bottom of the blank. Remember,

the top of the bowl is attached to the faceplate.

Turning

the Outside Turning

the Outside

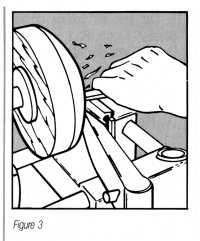

Using either a long bowl gouge or a shallow spindle gouge, turn

from the foot to the rim to create a form. (Figure 3) As the turning

progresses, constantly evaluate the form and occasionally stop to

readjust the tool rest to keep it as close to the wood as possible.

When satisfied with the outer shape, sand to the desired level,

turn a foot for a spigot chuck or flatten the base of the foot to

use a scrap block glued to the bowl blank using a paper glue joint.

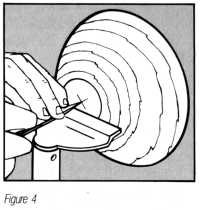

To properly center this block, bring the tool rest up close to the

base, with the height set just below midpoint. Then using a sharp

awl, make a very shallow indent at the exact center of rotation.

(Figure 4) Remove the turning from the lathe. Remove the bowl from

the faceplate. Apply yellow woodworkers glue to both the scrap block

and turning block and to the paper. Use the 5/8" brad-point drill

bit as explained before to locate the faceplate over the exact center

of the turning. Remove the drill bit and place the whole assembly

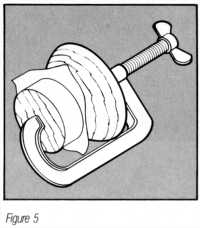

in a vise or clamp. (Figure 5) Leave there overnight to let glue

dry completely. Remove the clamp.

Turning

the Inside Turning

the Inside

Make sure that the speed dial is again at the slowest setting, mount

the faceplate with stock, stand to the left and turn the power on.

If all has gone according to plan, the piece will be centered. If

it appears that the pieces not perfectly centered, stop the power

and bring the tail stock assembly (using the live center) in to

help support the bowl blank. This will necessitate using the quill

in a slightly extended position, but this is good. The extended

quill will allow you to true up the exterior and sand as before.

Then, replace the live center with the Jacobs chuck and the largest,

sharpest drill bit that will fit within the area of the top, but

not larger than the planed inside diameter at the foot of the piece.

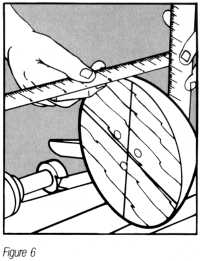

Measure from the top of the bowl to the top of the foot. (Figure

6) Transfer this measurement, minus ¼", to your depth stop with

the drill bit touching the stock. Using the quill feed, drill out

the center of the bowl to the depth indicated on the depth stop.

The extra ¼" is "in case". In case anything goes wrong…and if you

don’t plan on it going wrong, IT WILL! Next, using the bowl gouge,

remove the bulk of the inside of the bowl down to the already established

bottom. (Figure 7) Wall thickness is something to be decided by

each turner. However, one of the hallmarks of a good turner is that

whatever the wall thinness of thickness, it will be uniform from

rim to bottom (with a very slight thickening at the base allowed).

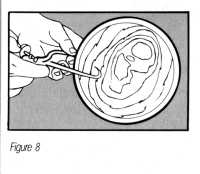

Stop the lathe and use calipers to gauge the thickness. Then remove

the thick spots as you go. (Figure 8) Using a freshly ground bowl

gouge, take a light finishing cut from rim to bottom. Sand to the

desired degree, apply the finish of your choice, remove from the

lathe and be careful not to drop it on the floor on the way in to

show your family and friends.

|